PEZY for hardware scaleups

Hardware scaleups operate in one of the fastest growing markets. Global demand for physical products, smart devices and connected systems continues to rise and companies that innovate quickly gain a clear competitive advantage. Yet many scaleups reach a point where a prototype or early product is no longer enough. They need production capacity, a reliable supply chain, industrialisation expertise and the ability to scale with confidence. This is where most hardware teams stall and where PEZY adds real value.

PEZY offers an end to end and integrated approach that brings design, engineering, industrialisation, sourcing and production together in one ecosystem. With a footprint in the Netherlands and Asia, small autonomous teams and strong shared services, we help scaleups accelerate time to market while reducing risk and limiting capital expenditure. Our global network of manufacturing partners makes it possible to scale without building your own factory and without compromising on quality or compliance.

We support scaleups with engineering depth, fast iteration, pilot manufacturing, supply chain creation and volume production. Each collaboration is tailored because every hardware business has different needs whether it operates in medtech, consumer hardware or industrial solutions. Our cell structure ensures ownership and flexibility, so teams can move fast and remain focused on outcomes. And we have a proven track record. From mobility solutions to health tech devices and consumer products, we help companies turn prototypes into scalable and reliable products that succeed in the real world.

PEZY is the partner for hardware scaleups that are ready to scale with speed, certainty and global reach.

Why hardware scaleups struggle to scale

Hardware markets grow quickly. New generations of consumer electronics, connected devices, wearables, medical products and industrial solutions enter the market every year. Demand for smart physical products continues to rise globally. But while the market expands, the path from prototype to large scale production remains a challenge for most teams.

From prototype to production is a critical and risky phase

Many scaleups succeed in building a working prototype yet quickly discover how difficult it is to turn that early version into a stable and manufacturable product. The transition from prototype to production requires choices that shape the entire future of the product. It involves maturing the design so it becomes reliable in real world use, setting up a repeatable and scalable production process, selecting and managing international suppliers, and understanding the realities of design for manufacturing and industrial constraints. At the same time scaleups must create a compliant and robust supply chain, keep costs under control without compromising quality, and navigate regulatory requirements in Europe and Asia.

This is often the moment where promising products stall. Internal teams are strong in innovation yet lack the specialised resources and experience needed to build a reliable and scalable hardware production system.

The capex barrier

Scaling hardware is expensive. Establishing production lines, tooling, sourcing and quality systems requires major capital expenditure. Many companies cannot or should not take on that financial burden too early. They need access to production and expertise without owning the infrastructure.

The talent challenge

Engineering talent is scarce. Hardware teams often struggle to recruit the multidisciplinary specialists they need at the right moment: system engineers, plastics experts, mechatronics specialists, quality engineers and supply chain experts. This slows down scaling and raises the risk of costly errors.

What hardware scaleups need to grow

Successful hardware scaleups share one thing: they work with partners who take joint responsibility for the entire journey from idea to industrial reality. To grow beyond the prototype phase they need engineering depth to mature the product and the industrialisation expertise required to prepare it for mass production. They depend on a reliable and flexible production footprint combined with quality systems that guarantee consistency at every stage.

They also need strong sourcing support and a supply chain they can trust, together with a clear understanding of regulatory and compliance requirements in the markets they want to enter. Above all, they need fast iteration from early proof to pilot manufacturing and a partner who understands both innovation and operations so the product can scale with confidence.

PEZY is an integrated innovation and industrialisation partner

PEZY brings design, engineering, prototyping, industrialisation, sourcing and production together in one continuous process. We operate with autonomous specialist teams supported by strong shared services in sales, finance, quality and program management. With more than 25 years of technical heritage and a footprint that connects the Netherlands with Asia, we help scaleups move from prototype to production with confidence.

One integrated ecosystem

Most scaleups work with a patchwork of different partners: a design studio for the early concept, a prototyping house for the first build, an engineering team for refinement, a supplier for components and a manufacturer for production. Each handover adds time, introduces risk and increases the chance that knowledge gets lost along the way.

PEZY brings all of these capabilities together in one integrated ecosystem, which means one team, one process and one clear line of accountability. This unified approach shortens lead times, prevents costly errors and creates a seamless transition from early innovation to reliable production.

What PEZY offers hardware scaleups

Hardware scaleups need more than engineering support or production capacity. They need a partner who can guide them through the entire journey from early concept to global manufacturing. PEZY offers a complete and integrated set of capabilities that help scaleups turn prototypes into reliable, manufacturable and scalable products.

Engineering and technical depth

Our multidisciplinary teams bring deep expertise across plastics engineering, system engineering, mechatronics, DfM and DfX, as well as embedded development through specialised partners. We work with a strong understanding of materials, sustainability considerations, testing and validation. This combination allows us to transform early prototypes into robust and manufacturable products that are ready for real world scale.

Rapid iteration and early proof

Speed is essential for scaleups. Through fast prototyping, pilot manufacturing and short decision cycles we reduce time to market and help teams test assumptions earlier. This approach makes it possible to refine the product quickly, resolve issues while they are still manageable and build confidence before committing to full industrialisation.

Industrialisation and sourcing

We take responsibility for establishing the manufacturing foundation that every hardware scaleup needs. This includes maturing the design for manufacturing, defining tooling strategies, creating reliable production processes and establishing strong quality and testing frameworks. We also manage supplier selection, cost optimisation and the complete setup of packaging, logistics and supply chain operations. This creates a clear and reliable pathway toward stable production.

Production and scale up

With connected facilities in the Netherlands, Malaysia and Singapore we support the full production lifecycle, from pilot runs to low volume builds and high volume manufacturing. Our teams ensure quality assurance, auditing and continuous improvement across all production stages. Scaleups can grow without investing in their own factories and without compromising on quality or reliability.

Compliance and regulatory insight

Many products especially in medtech and personal care require strict regulatory discipline. PEZY helps companies prepare their products and documentation for the relevant regulatory frameworks and ensures that compliance is built into the process from the start. This reduces risk and shortens the path to market entry in Europe, Asia and beyond.

A flexible model built for scaleups

Every hardware scaleup is different. Some need engineering. Some need sourcing. Some need full scale industrialisation. Some need a long term partner for production. Our collaboration model adapts to the needs of the business.

Small autonomous PEZY project teams

Every project at PEZY is driven by a dedicated autonomous team with full ownership of the outcome. These small PEZY project teams bring together all the skills required for success and operate with the speed and focus that only compact teams can achieve. Because there are no unnecessary layers, decisions are made quickly and projects move forward without friction.

Supported by shared services

These autonomous teams are strengthened by a set of central functions that ensure stability and reliability. Program management, quality and regulatory expertise, finance and commercial support and global supply chain connections all work behind the scenes to provide structure. This model combines the agility of a small team with the operational strength of a mature organisation.

A transparent way of working

Throughout the entire process we provide complete clarity. Teams know what decisions are required, which risks need attention, how timelines develop and what costs to expect at each stage. We guide scaleups through every transition from prototype to pilot production and finally to full scale manufacturing. This transparency allows companies to make informed decisions and ensures they always know where they stand.

Proven impact for hardware scaleups

PEZY has helped hardware scaleups grow from early concept to real world products across health tech, personal care, consumer electronics and industrial solutions. Our work includes mobility devices, medical testing devices, communication tools, smart wearables and consumer hardware that are now operating in the market. These projects show how an integrated approach reduces time to market, lowers capital requirements and brings stability to production even at higher volumes. They also demonstrate the value of building a reliable supply chain that can scale globally and maintain consistent quality throughout the entire lifecycle. Real teams turning real ideas into real products.

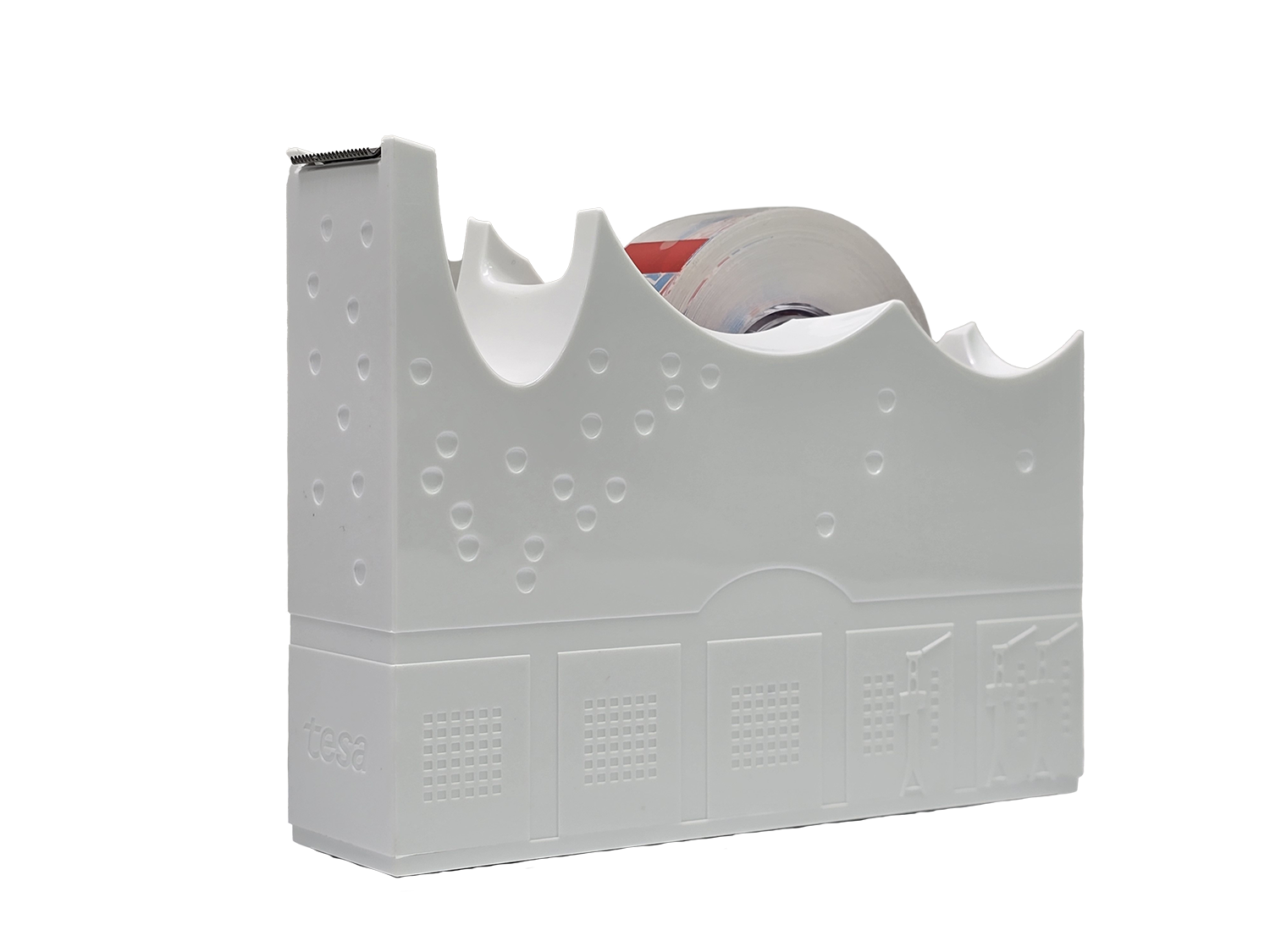

Tesa Tape Dispenser

A tape dispenser in iconic style

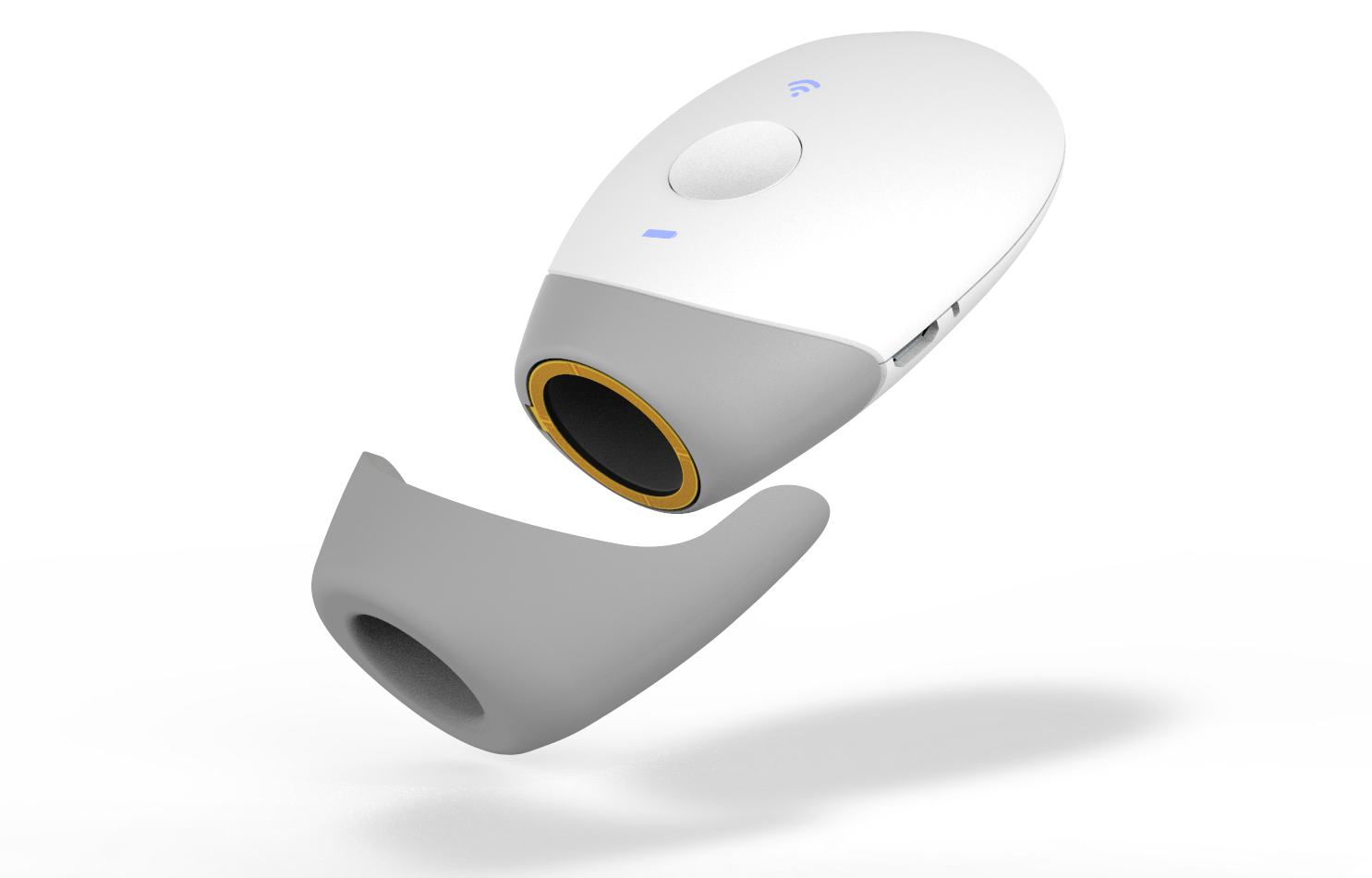

Skinly

Understanding your skin through Artificial Intelligence

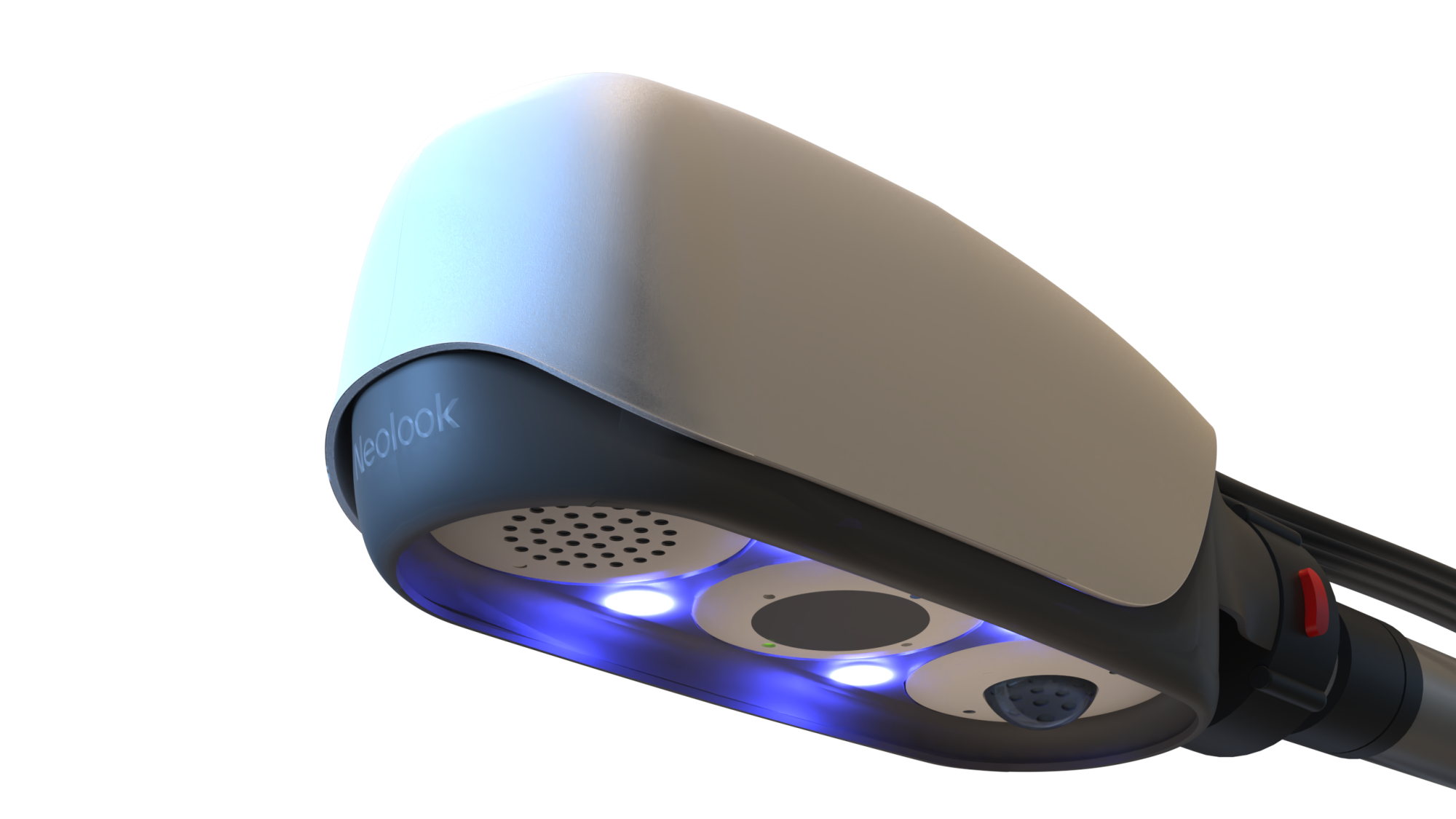

Neolook One

Video-Augmented Monitoring in Neonatal and Pediatric Care

Hable one

An ingenious braille-operated keyboard for improving multimedia accessibility for the visually impaired

Victron Energy EV Charger

An EV car charger specifically designed for the home market

Philips Living Color

Unique product with PET bottle technology

Quva

Less waste, fresh for longer

Philips Avent

Smart details and materials for comfortable breast pump

Why hardware scaleups choose PEZY

Scaleups choose PEZY because we bring together what most organisations treat as separate worlds. We combine engineering excellence with industrialisation expertise and production capabilities, all supported by global supply chain access and regulatory understanding. Our teams work with speed, ownership and craftsmanship and move with the confidence that comes from decades of technical heritage. This combination allows us to make hardware real and scalable in a way few partners can match.

Ready to scale your hardware?

PEZY is the partner for hardware scaleups that want to grow with speed, certainty and global reach. We help companies move from prototype to production with an integrated ecosystem designed for scale.

Let’s build your next stage together.