From idea to tangible product

A good idea only gains true value once you can hold it in your hands. Prototyping makes concepts tangible and provides immediate insight into form, functionality, and usability.

Prototyping is an essential step in the journey from idea to market-ready product. There are several reasons to develop prototypes. First and foremost, to test and validate whether a functionality that works digitally also performs as intended in practice. But also to create a fully functioning demonstrator, giving stakeholders and investors tangible proof that an innovation has the potential to conquer the market.

Only when critical factors such as functionality, design, and composition have been demonstrated can the actual — and often costly — large-scale production process be started. At PEZY, we develop physical prototypes that accelerate design decisions, reduce risks, and make the transition to production more reliable.

What is prototyping?

At PEZY, a prototype is never just a model — it is a strategic step in product development. While a digital design can show what is possible, a physical prototype reveals what truly works. Our teams combine industrial design, plastics engineering, and production expertise to create prototypes that are directly relevant to the next phase. This means we look beyond form and function, focusing also on manufacturability, material selection, and circularity. A prototype becomes more than a test object — it is a concrete learning tool that guides the entire journey toward market introduction.

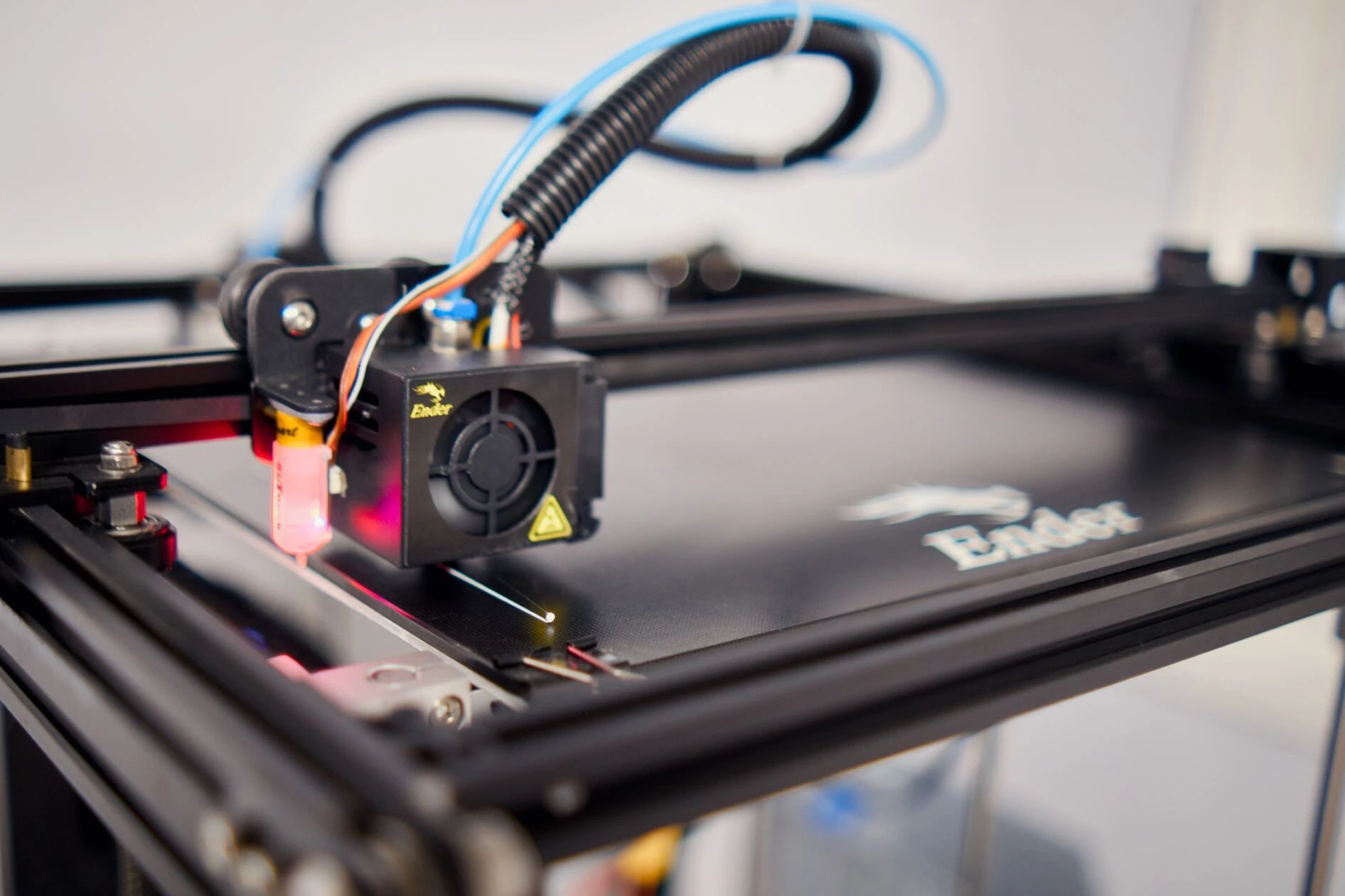

Prototyping at PEZY is always iterative and multidisciplinary. Our designers work closely with engineers, material specialists, and production managers to quickly develop and validate multiple variants. This can be a simple form study that comes out of our 3D printers in a single day, or a fully functional model tested in the Plastics Factory for moldability, durability, and assembly. Each iteration provides valuable insights that help us improve the product step by step. This accelerates the process and reduces risks, because critical decisions are validated early on.

We also embed circular principles in every prototyping process. Instead of waiting until production to consider sustainability, we test early how recycled or biobased materials perform, and how a product can be designed for easy disassembly or reuse at the end of its lifecycle. This gives the term “future-proof” a very concrete meaning in our prototypes. Whether it concerns low-fidelity, high-fidelity, or pre-production models, PEZY ensures that every prototype is not only a realistic representation of the product, but also a step closer to a scalable and sustainable solution.

Why prototyping is essential for product development

At PEZY, we believe prototyping is the fastest way to learn. Instead of endlessly refining digital models, we make ideas tangible and gather feedback from users, engineers, and stakeholders. This shows us immediately how a design behaves in practice: is it intuitive, ergonomic, safe, and appealing? These early insights shorten project lead times significantly, because we resolve issues before they grow costly or complex.

Prototyping also helps reduce risks. Every mistake uncovered in a prototype prevents expensive corrections later in tooling or production. With our multidisciplinary approach, we identify not only technical challenges but also issues in assembly, material selection, and circularity. This proactive process eliminates surprises during scale-up and creates a streamlined path to market introduction. The result: products that reach the market faster, more reliably, and with greater sustainability.

Another crucial benefit is persuasion. Investors, partners, and end-users only truly understand a product once they can hold it in their hands. A well-executed prototype or small series from our rapid tooling facilities gives stakeholders the confidence that an idea is not just well thought out, but also manufacturable and scalable. In this way, prototyping becomes the bridge to production: from first sketches to small pilot runs for validation and market testing, and ultimately the stepping stone to large-scale manufacturing in our Plastics Factory.

Why prototyping is essential

Learn faster

Prototyping is the fastest way to learn. An idea remains abstract as long as it exists only in digital form; only when it can be held in the hand does its real behavior become clear. Direct feedback from users, designers, and engineers provides insight into crucial questions: is the ergonomics correct, is the interaction intuitive, how does the product feel in use? By testing these aspects early, improvements can be made immediately. This accelerates development and prevents time and budget from being wasted on assumptions that fail in practice.

Reducing risks

Every problem discovered in a prototype prevents far greater costs later in the process. By validating functionality, materials, and assembly early, prototyping ensures that errors are caught before expensive tooling or large-scale production begins.

At PEZY, we use a multidisciplinary approach to identify not only technical challenges but also risks related to manufacturability, durability, and sustainability. By integrating circular design principles from the start, we also assess how choices affect end-of-life reuse or recycling. This way, we create a streamlined path to market introduction where surprises are minimized and reliability is maximized.

Reducing risks through prototyping means greater confidence at every step — from the first sketch to series production — ensuring that innovations don’t just reach the market faster, but also with higher quality and long-term resilience.

Convincing stakeholders

A good prototype speaks volumes. Investors, partners, and end-users only truly understand what a product can do once they experience it physically. For our clients, this makes their story to stakeholders far more compelling: a demonstrator turns a promise into something concrete. In our projects, we often see that a well-executed prototype makes the decisive difference in funding rounds, partnership agreements, or market tests. That’s why at PEZY we ensure that prototypes are not only functional, but also carry the right design quality and finish to inspire trust and generate enthusiasm.

Bridge to production

Prototyping is not the end of the journey — it is the stepping stone toward full-scale manufacturing. At PEZY, we use rapid tooling and pilot production runs to create small series that behave just like the final product. These series allow us to validate assembly, tolerances, and performance under real-world conditions, giving both our teams and our clients the confidence to move forward.

Because our Protolab and Plastics Factory are directly connected, we can seamlessly scale from a handful of prototypes to thousands of units without losing time or quality. This integrated approach ensures that insights gained during prototyping translate directly into smarter tooling, optimized processes, and a smoother industrialization phase.

By treating prototyping as a bridge to production, we reduce uncertainty, accelerate time-to-market, and deliver products that are ready not just for testing, but for success in large-scale deployment.

Methods and techniques for prototyping

In the PEZY Protolab, we develop the very first tangible versions of a product. Here, speed is everything: within a short timeframe, we create models that can immediately be tested for form, dimensions, and ergonomics. Once the basics are validated, we move into our own PEZY Plastics Factory. Equipped with a full infrastructure of 3D printers, a tool shop, injection molding machines, and a wide range of testing and finishing tools, this facility enables us to scale quickly from sketch to realistic prototypes.

Our capabilities are broad and flexible. Depending on the project’s goals, requirements, and lead time, we apply techniques such as:

-

3D printing (SLA, SLS, FDM) for fast form and function testing

-

CNC machining for strong and highly precise components

-

Vacuum casting / urethane molding for small series with excellent surface quality

-

Rapid tooling: soft tooling and aluminum molds for low-volume injection molding

-

Conventional injection molding combined with pilot tooling for highly representative end products

And it doesn’t stop with plastics alone. In our Plastics Factory we also provide metalworking capabilities, integrating elements such as metal inserts or upholstery. This enables us to build complete prototypes and small series that come as close as possible to the final product.

Every method comes with its own strengths and trade-offs in terms of speed, material choice, tolerances, and costs. Because we have all these technologies under one roof, we can always select the optimal route and switch quickly between methods. This ensures that every prototype perfectly matches the stage of the project and the ambitions of our client.

Examples of our developed products

Pezy develops innovative products for a wide range of markets, from consumer goods to medical devices.

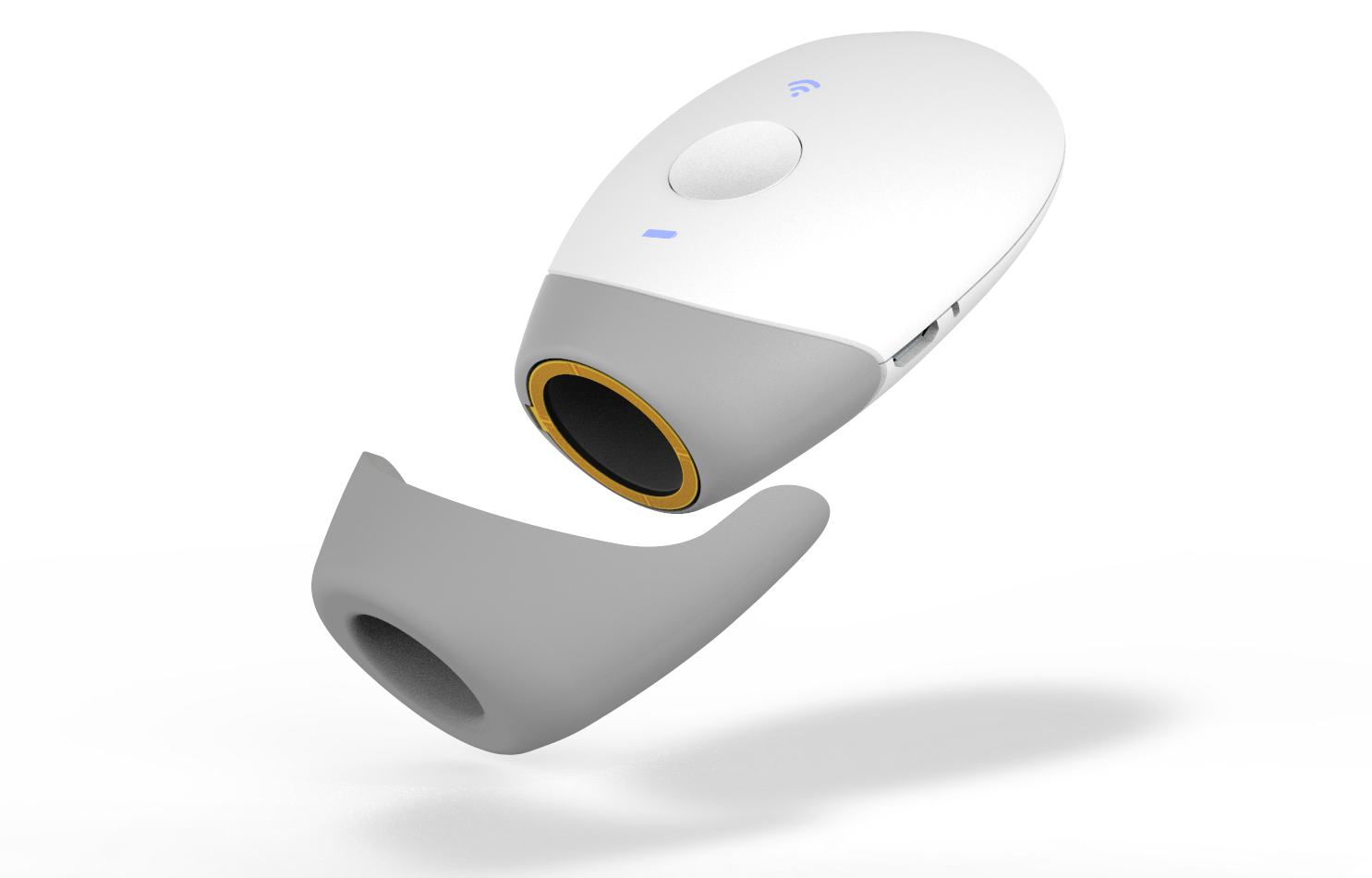

Skinly

Understanding your skin through Artificial Intelligence

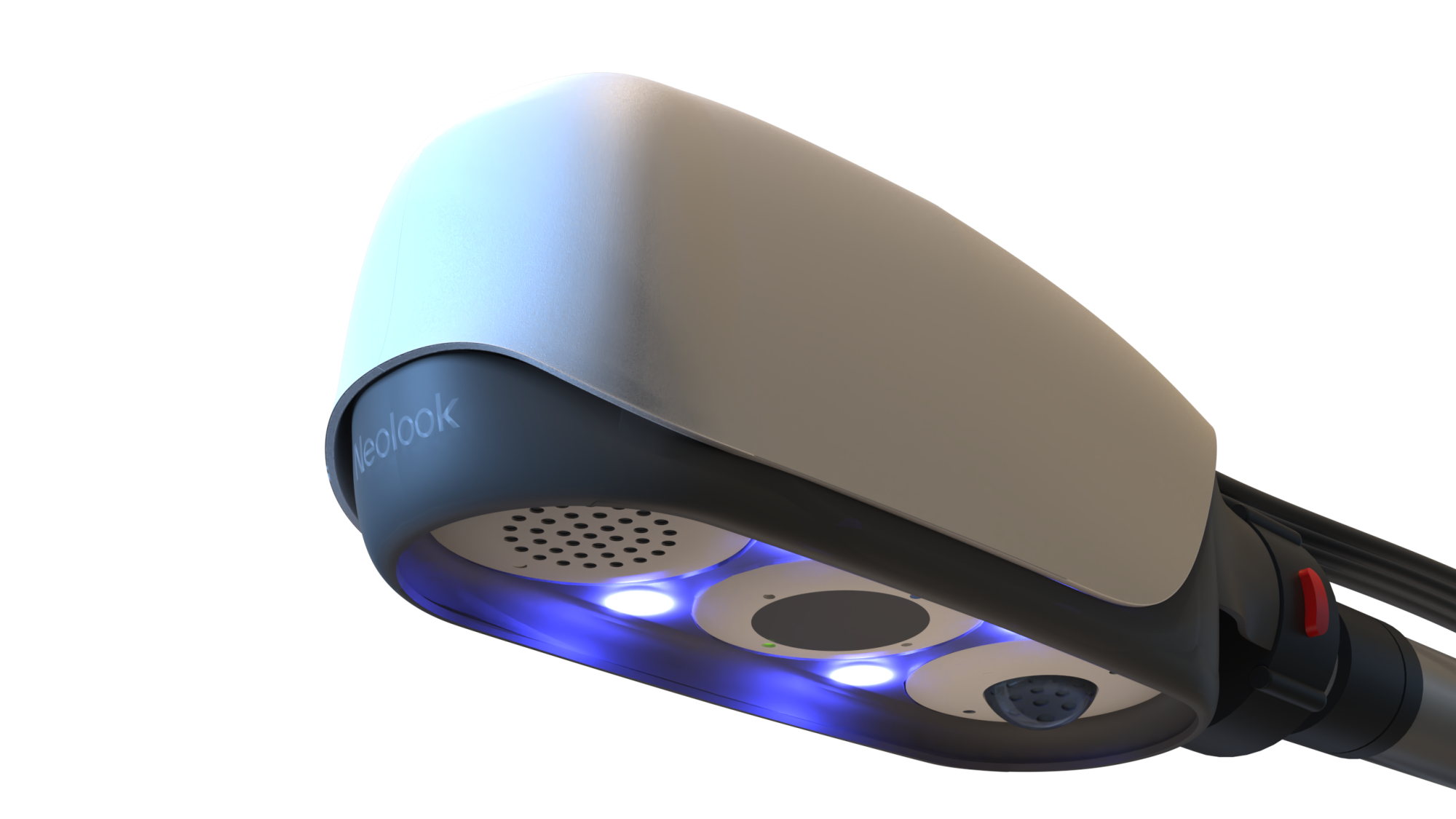

Neolook One

Video-Augmented Monitoring in Neonatal and Pediatric Care

Hable one

An ingenious braille-operated keyboard for improving multimedia accessibility for the visually impaired

Victron Energy EV Charger

An EV car charger specifically designed for the home market

Philips Living Color

Unique product with PET bottle technology

Quva

Less waste, fresh for longer

Philips Avent

Smart details and materials for comfortable breast pump

Dorel Quinny

The First-Ever Foldable Plastic Buggy