The future of medical product development lies in preserving value, not consuming resources.

Healthcare is a sector of progress, full of innovations that improve lives. But behind that progress lies an uncomfortable reality: healthcare is also one of the largest producers of waste. From syringes and infusion systems to packaging and diagnostic tools, countless products are discarded after a single use every day. What once symbolized safety and efficiency has become, in a circular world, a structural problem.

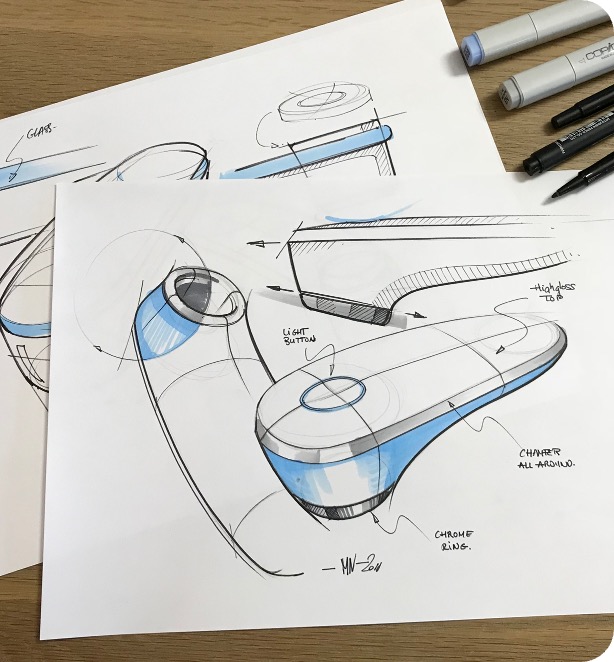

For product developers in healthcare, this poses a complex challenge. How do you design medical devices that meet strict safety standards while also addressing material use, reusability, and CO₂ impact? The transition from linear to circular requires not only new materials but also a fundamentally different way of thinking within design and development processes. Product development is no longer driven solely by cost or performance optimization, but by the ability to preserve value throughout the entire life cycle.

Circular product design forces us to look ahead—beyond first production and initial use. It calls for designs that are prepared for disassembly, reuse, and recycling, and for supply chains that recover rather than lose resources. Within the HealthTech sector, this presents a major opportunity: innovation and sustainability can go hand in hand, provided circularity is embedded from the design stage onward.

From linear to circular in medical product development

With over thirty years of experience in product development, engineering and material research, PEZY helps organizations in HealthTech and Care turn ideas into feasible, future-proof products. Our teams work from concept to validation, combining design, plastics engineering and manufacturing technology in one integrated approach. This way we bring circularity from vision to reality, with a focus on functionality, safety and compliance.

Through our expertise in design for and from recycling, we connect innovation with responsibility. We understand both the possibilities and the limitations of recycled and biobased materials, and we know how to translate this understanding into reliable medical applications. With this knowledge we develop products that are technically feasible and contribute to a more sustainable healthcare chain.

The complexity of (circular) product development in healthcare

Medical product development is rarely straightforward. Designing for healthcare means operating within a field defined by strict safety standards, regulatory requirements and rapidly evolving technologies. Every design decision impacts performance, reproducibility and validation, as well as the ecological footprint of the product.

In this context, innovation requires more than technical expertise alone. It demands a deep understanding of materials, user behavior and production processes, combined with the ability to bring all these elements together in one manufacturable design. Our design philosophy aligns with the principles of the R-ladder, where value preservation is central. Think of Design for Repair, Reuse and Recycling: designs that last longer, use resources more intelligently and are prepared for a second life. Circularity, in this sense, is not an end in itself but a natural outcome of good product thinking.

Those who truly understand product development in healthcare know how fine the line is between feasible, safe and sustainable. Experience shows that success lies in connecting disciplines such as design, engineering, material research and manufacturing. When these come together, innovation emerges that works in practice, in production and within the healthcare environment itself.

New materials as building blocks for sustainable product development

New material technology plays a key role in the future of medical product development. While conventional or mechanically recycled plastics often fail to meet medical standards, biobased and chemically recycled plastics open up new possibilities. Closed material loops, in which resources are recovered and reused, are also increasingly becoming part of the design strategy.

For many medical manufacturing companies, these possibilities are still relatively uncharted territory. Yet they hold the key to creating products that are safe, reusable and future-proof. This requires knowledge of material properties and validation processes, as well as the courage to rethink business cases and usage contexts. It is in this combination of innovation and responsibility that true progress emerges.

The use of bioplastics and recycled plastics offers not only ecological benefits but also enhances design freedom and functional optimization. By aligning material innovation with the requirements of the healthcare sector, new generations of products become possible, meeting the highest safety and quality standards while contributing to a more sustainable value chain.

Collaboration as a driver of medical product development

The development of future-proof medical products requires close collaboration between designers, researchers, and healthcare professionals. In a domain where safety, regulation, and innovation constantly intersect, real progress only happens when knowledge and practice come together. That’s why we actively engage in networks that stimulate and accelerate innovation in HealthTech.

PEZY: partner in medical product development

PEZY develops medical products where design, engineering and manufacturability come together. We support organizations that aim to innovate in healthcare and help transform ideas into functional, safe and future-proof products.

Our multidisciplinary teams in Eindhoven, Groningen and Utrecht work across the entire development process, from concept and prototype to validation and production-ready design. By integrating design, material research and manufacturing technology, we shorten the time to market and increase certainty at every stage of development.