From idea to innovative plastic product

A strong plastic product always starts with a good idea, but it is only through the right engineering that this idea becomes reality. Plastics engineering revolves around the strategic use of materials, production techniques and design principles to develop functional, reliable and sustainable products. Most of the products we design consist of multiple plastic components, each with specific requirements in terms of shape, function and construction. That is precisely why in-depth knowledge of plastics, mechanical behaviour and manufacturability is indispensable.

Plastics engineering is one of the most important specialisms within our organisation. We understand in detail how plastic behaves, how it can be processed and how we can translate a concept into a producible, high-quality end product. Thanks to our integrated approach, we guide the entire process: from the initial sketch design to the production of the final component.

Plastics engineering and technical plastics

Our strength lies in the combination of design, materials science and manufacturing expertise. Thanks to decades of experience, we understand the behaviour of a wide range of plastics, from commonly used materials such as ABS, PC and PP to innovative biopolymers and high-performance engineering plastics. For each application, we recommend the material that best suits the desired strength, flexibility, chemical resistance or durability.

But plastics engineering goes beyond just the choice of materials. Smart and thoughtful engineering makes the difference between a product that works and a product that excels. We optimise wall thicknesses for maximum stability with minimal material use, determine precise tolerances so that assemblies run smoothly, and design products that are simple and efficient to manufacture. We always look at the big picture: from product performance to supply chain requirements.

Our expertise in production techniques such as injection moulding, blow moulding, overmoulding and hybrid production technologies ensures that even complex parts can be manufactured. We contribute ideas about parting lines, draft angles, rib structures and inserts, so that the design not only functions well, but is also suitable for scalable industrial production.

Development of customised plastic components

Every product and every application requires customisation. That is why we develop plastic components that fully meet the technical, functional and aesthetic requirements of our customers. We do this using advanced simulations and digital analyses such as:

- Mould flow analyses to predict filling behaviour and shrinkage

- Finite Element Analysis (FEA) to validate strength, stiffness and durability

- Thermal simulations to optimise heat flows, cooling times and temperature effects

By applying these calculations early in the process, we minimise risks and shorten development times. Any bottlenecks are resolved before the first mould is built, which prevents costly iterations and adjustments.

Prototyping and pilot production

An important part of our plastics engineering is our own prototyping and testing facility. In our tool shop, we have:

- 3D printers for rapid concept and functional prototypes

- A fully equipped mould-making shop

- Injection moulding machines for small series

- Various measuring, testing and finishing tools

This allows us to carry out all stages of the development process under one roof. We create realistic, tangible prototypes that fully correspond to the final product. These prototypes form the basis not only for technical validation, but also for user testing, design reviews and pilot production.

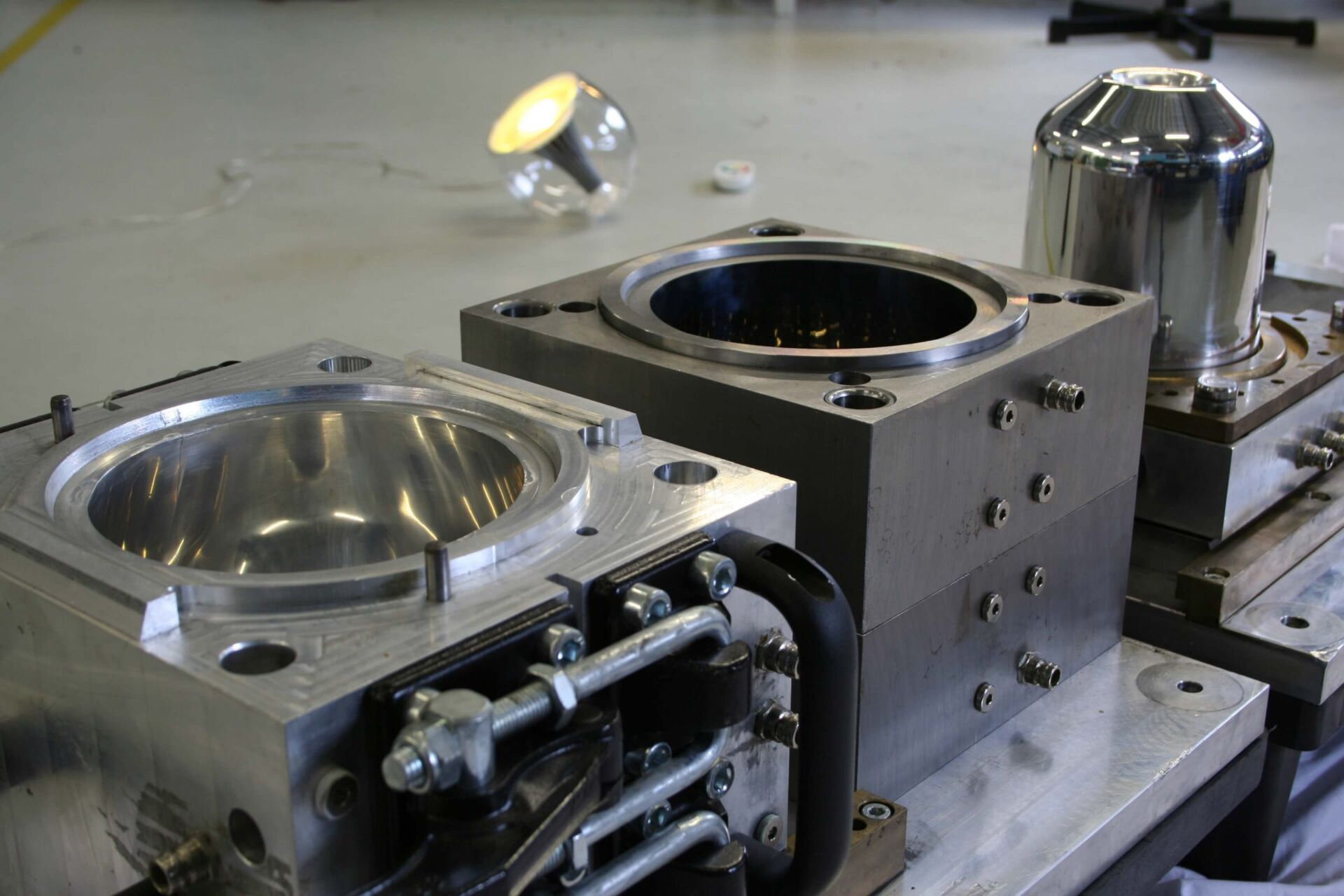

Expert knowledge of plastic moulds

The quality of a plastic product depends entirely on the quality of the mould. Thanks to our in-house mould making facility and years of experience, we know exactly how to design and optimise moulds to achieve the perfect balance between functionality, service life and cost efficiency.

We carefully examine aspects such as heat management, discharge systems, wear-sensitive areas and optimisation of cooling circuits. Our engineers work closely with production to ensure that every mould delivers the desired result right from the first injection run. Our in-house tool shop also enables us to make adjustments, tests and modifications quickly — something that makes a difference in terms of time and budget for many projects.

Sustainable plastics

Although plastic is often wrongly associated with disposable products, sustainability is an important pillar of professional plastic engineering. The components we develop are designed for a long service life, reliable performance and optimal recyclability.

We have in-depth knowledge of biodegradable plastics, recycled raw materials (PCR and PIR) and biobased alternatives. Depending on the application, we advise on circularity, reparability and material choices that have the lowest possible ecological footprint.

Our engineers contribute ideas throughout the entire product life cycle: from raw material selection to end-of-life scenarios. In this way, we actively contribute to more sustainable product chains and innovative applications that are ready for the future.

Have plastic products manufactured at PEZY

With over thirty years of experience, PEZY has built up a development environment in which design, technical development and production are perfectly aligned. Rather than being a single step in the process, we guide the entire process: from initial concept to full-scale series production. This ensures an efficient workflow in which speed, consistency and high quality are key.

Our added value lies in our integrated approach. Industrial designers, plastics specialists, electronics experts and production managers combine their knowledge to optimise every part of the product. This does not only happen internally; we also work closely with a carefully selected network of partners. These include experienced mould makers and test laboratories within Europe, supplemented by production partners in Asia. Thanks to this combination of in-house expertise and reliable external specialists, we ensure that innovative ideas are actually developed, validated and scaled up to end products.