Innovation starts here

A brilliant idea is only the beginning. The real challenge lies in turning that idea into a product that works, can scale, and creates impact. At PEZY, we understand how complex plastics product development can be. It requires in-depth material knowledge, smart design, and a clear understanding of manufacturing processes. That exact combination makes us unique: we guide organizations from the very first sketch all the way to mass production, ensuring that innovative ideas reach the market faster and make a lasting difference.

Whether it concerns a medical device, a consumer product, or an industrial solution, we make sure the design is feasible, functions reliably, and is ready for the future—always with sustainability in mind.

From concept to market introduction

Plastics product development is more than building a prototype. It is a careful process in which every decision determines the quality and lifespan of the final product. At PEZY, we always start by sharpening the value proposition and understanding user needs. What problem should the product solve? How will it be used? Under which conditions will it perform?

A key element of our approach is the value of early proof. We validate ideas and assumptions as early as possible, allowing us to learn faster, avoid surprises, and move forward with confidence. Our engineers translate insights into smart designs and technical solutions, supported by CAD models, simulations, and strength calculations.

We then bring ideas to life with prototypes that we thoroughly test and validate. These early proofs provide valuable insights and accelerate the path to a reliable end result. Thanks to our in-house Pilot Factory, we can validate quickly and then seamlessly scale up to small series and prepare the smooth transition to mass production. In doing so, we bridge the gap between development and realization—without losing valuable time.

Sustainability as a starting point

While many development processes still focus mainly on functionality and cost, PEZY takes it one step further. We believe that every product should also contribute to a better future. That’s why circularity is embedded in all our projects.

We design products that are not only suitable for recycling but also made from recycled or biobased materials. Within the European PolyCE consortium, we developed a proven methodology called Design for and from Recycling. This makes sustainable choices tangible and practical. From material testing and disassembly studies to recyclability assessments, we integrate circular thinking right from the design phase—ensuring that products are ready for a truly circular economy.

Innovation in plastics product development that works

Our strength lies in the combination of creativity and technical depth. We bring together design, material knowledge, and manufacturing expertise in one integrated process. With decades of experience, we know exactly how plastics behave and where their limits lie. Whether it concerns widely used materials such as ABS, PC, and PP, innovative biopolymers, or high-performance composites, we advise on the best choice for the intended application, usage, and product lifetime.

But material selection is only part of the story. Smart engineering is just as crucial. We optimize wall thicknesses for strength and cost, define tolerances so precise that assemblies fit seamlessly, and take the entire supply chain into account. Complex parts become manufacturable thanks to our in-depth expertise in injection molding, blow molding, and overmolding—always with scalable production in mind.

With advanced simulations—such as mould flow analysis, finite element analysis (FEA), and thermal calculations—we can predict product behavior long before the first mold is built. This reduces risks, accelerates development, and prevents costly redesigns later in the process.

What truly sets us apart is our ability to combine this technical precision with speed and pragmatism. In our own prototyping and pilot facilities, we translate digital simulations into physical test models. This allows us to validate immediately whether a design not only looks right on paper but also performs reliably in practice. The result: products that are robust, cost-efficient to manufacture, and meet the highest quality standards.

Examples of our developed products

Pezy develops innovative products for diverse markets, ranging from consumer goods to medical devices.

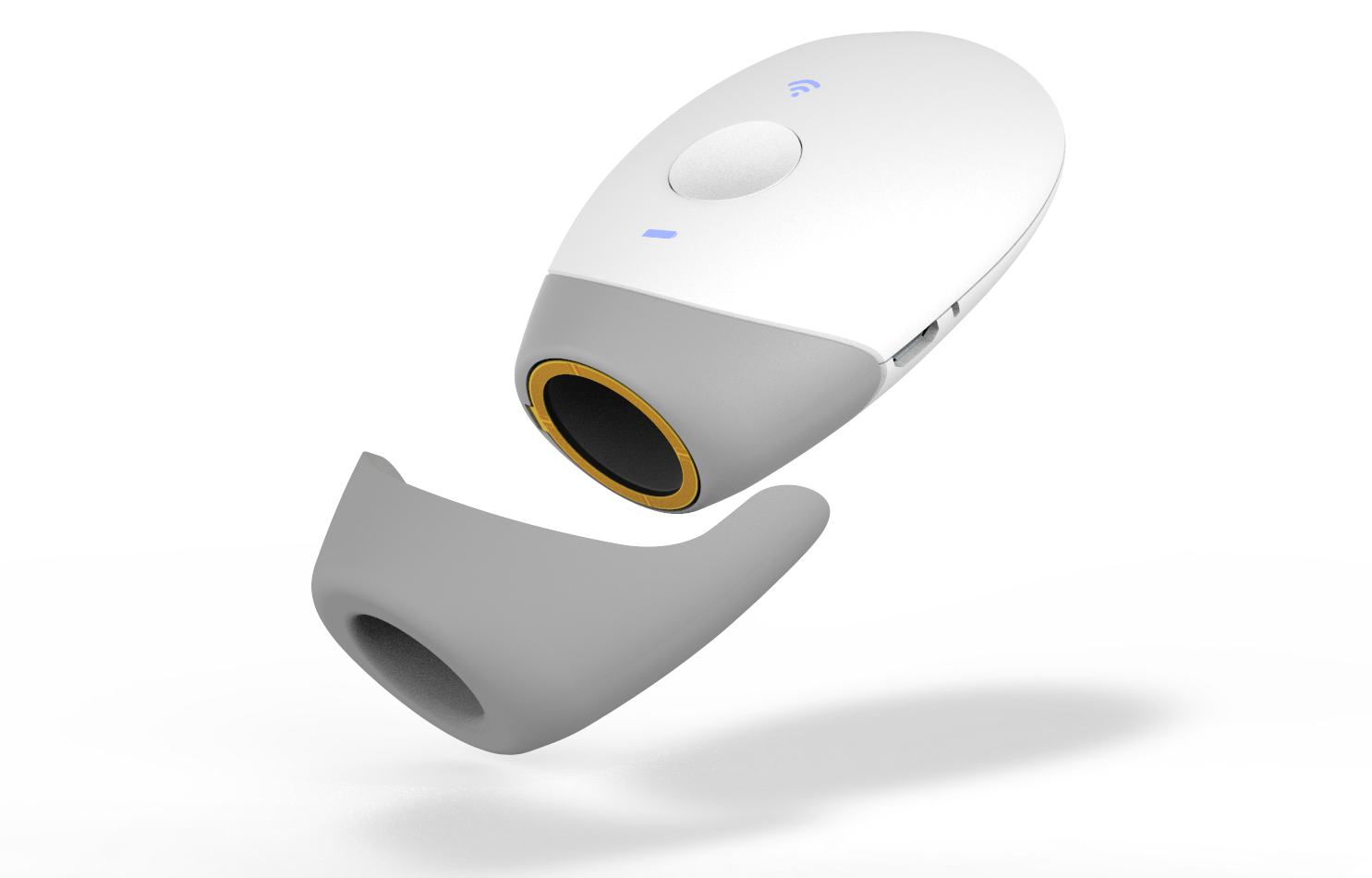

Skinly

Understanding your skin through Artificial Intelligence

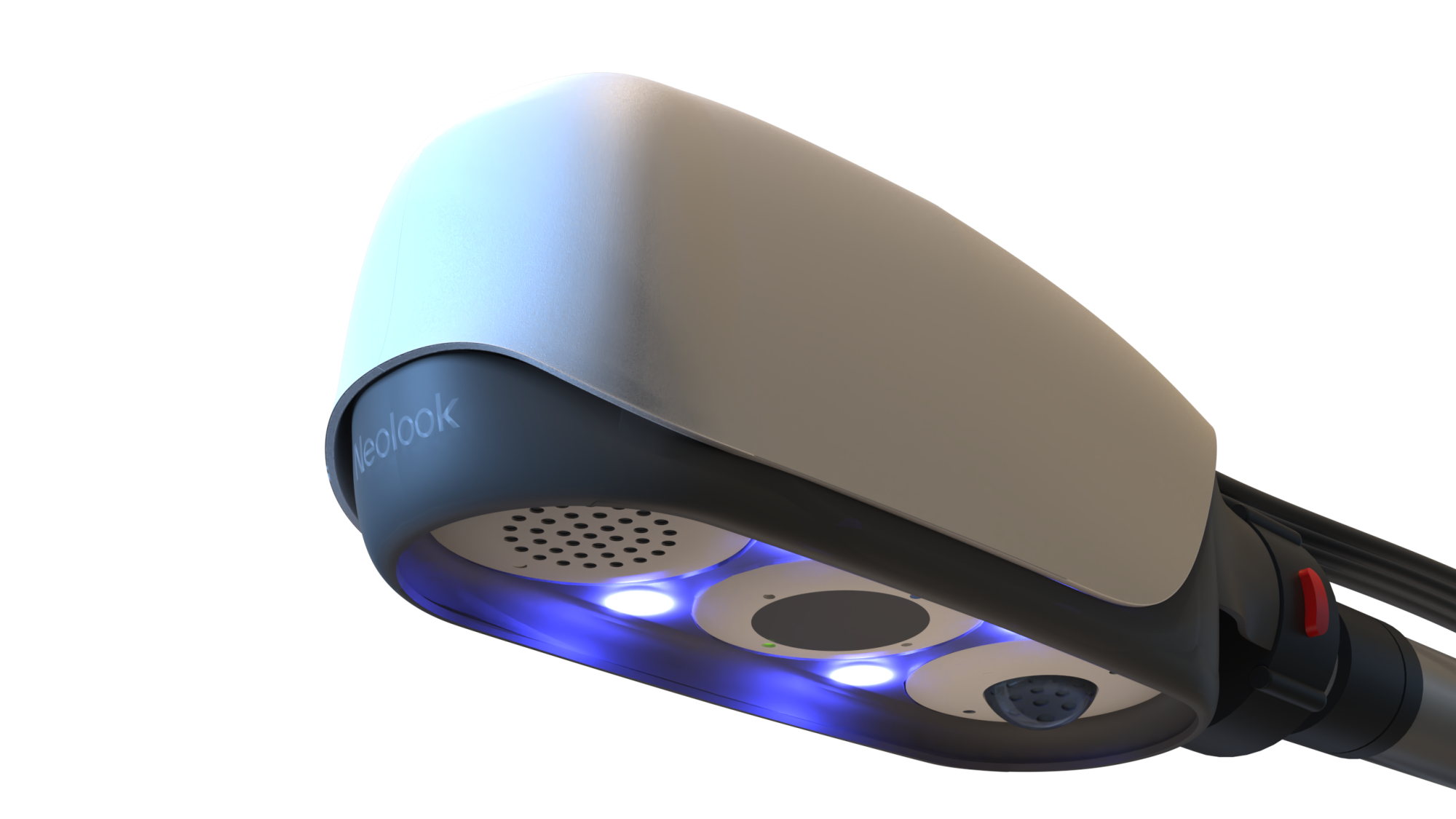

Neolook One

Video-Augmented Monitoring in Neonatal and Pediatric Care

Hable one

An ingenious braille-operated keyboard for improving multimedia accessibility for the visually impaired

Victron Energy EV Charger

An EV car charger specifically designed for the home market

Philips Living Color

Unique product with PET bottle technology

Quva

Less waste, fresh for longer

Philips Avent

Smart details and materials for comfortable breast pump

Dorel Quinny

The First-Ever Foldable Plastic Buggy

Projects that make a difference

Our approach is not just theory. We have successfully brought dozens of projects to market. For Philips Avent, we developed a new generation breast pump: more comfortable, quieter, and easier to use. For Hable, we managed the entire journey from the first prototype to series production of a braille keyboard that makes smartphones more accessible for the visually impaired. And for Victron Energy, we designed a robust charging solution for electric vehicles—weatherproof, durable, and ready for the consumer market.

These cases illustrate what we do every day: turning complex challenges into products that add real value for users and are fully prepared for mass production.

Why collaborate with PEZY as your plastics product development partner

With more than thirty years of experience, PEZY has built a unique infrastructure where design, engineering, and manufacturing come together seamlessly. We are not just one link in the chain—we take full responsibility from idea to series production. This creates a streamlined process where speed, quality, and reliability are always top priorities.

Our strength lies in our multidisciplinary approach: industrial designers, plastics engineers, electronics specialists, and production managers work closely together to get every detail right. We do this not only in-house but also in collaboration with a broad network of trusted partners—from specialized mold makers and testing facilities in Europe to manufacturing partners in Asia. This way, we ensure that innovative products don’t remain concepts on paper but actually reach the market.