There is a PEZY factory for that

The journey from initial design to actual tangible product is intensive, complex and requires close collaboration between designers, engineers and production specialists. Each product must undergo multiple rounds of testing, validation and optimisation.

For many organisations, it is difficult to access the right expertise, equipment and production facilities. That is why PEZY has consciously invested in its own production environment where small batch production is central, supplemented with high-quality tools and a fully equipped mould making facility. This allows us to shorten lead times, increase quality and create a unique development process in which speed and precision go hand in hand.

From concept to reality with small batch production

A product that looks perfect on paper must prove itself in practice. By producing prototypes, trial series and test models in small batches, we gain insight into manufacturability, material behaviour and user experience. Our approach to small batch production makes it possible to quickly realise tangible products, even before mass production comes into the picture.

Whereas many traditional manufacturers work exclusively with large volumes, we focus on the phase in which flexibility and speed are most important. This allows designs to be modified and retested in short cycles, without wasting valuable time on long delivery times or external dependencies.

The PEZY Pilot Factory in Groningen

Our PEZY Pilot Factory in Groningen is the heart of our small batch production. This factory is fully equipped with versatile and modern machinery, ranging from injection moulding machines and welding equipment to extensive testing and finishing setups. Here, we can carry out the entire process: from digital 3D model to high-quality physical component.

Because we have all the expertise in-house, we can quickly switch between different production steps. This makes the factory ideal for validating initial versions, optimising production methods and producing small series for market introductions, pilot runs or technical verification.

Greater control over manufacturability, quality and risks

Our PEZY Pilot Factory in Groningen is the heart of our small batch production. This factory is fully equipped with versatile and modern machinery, ranging from injection moulding machines and welding equipment to extensive testing and finishing setups. Here, we can carry out the entire process: from digital 3D model to high-quality physical component.

Because we have all the expertise in-house, we can quickly switch between different production steps. This makes the factory ideal for validating initial versions, optimising production methods and producing small series for market introductions, pilot runs or technical verification.

Our mould making: speed and precision combined

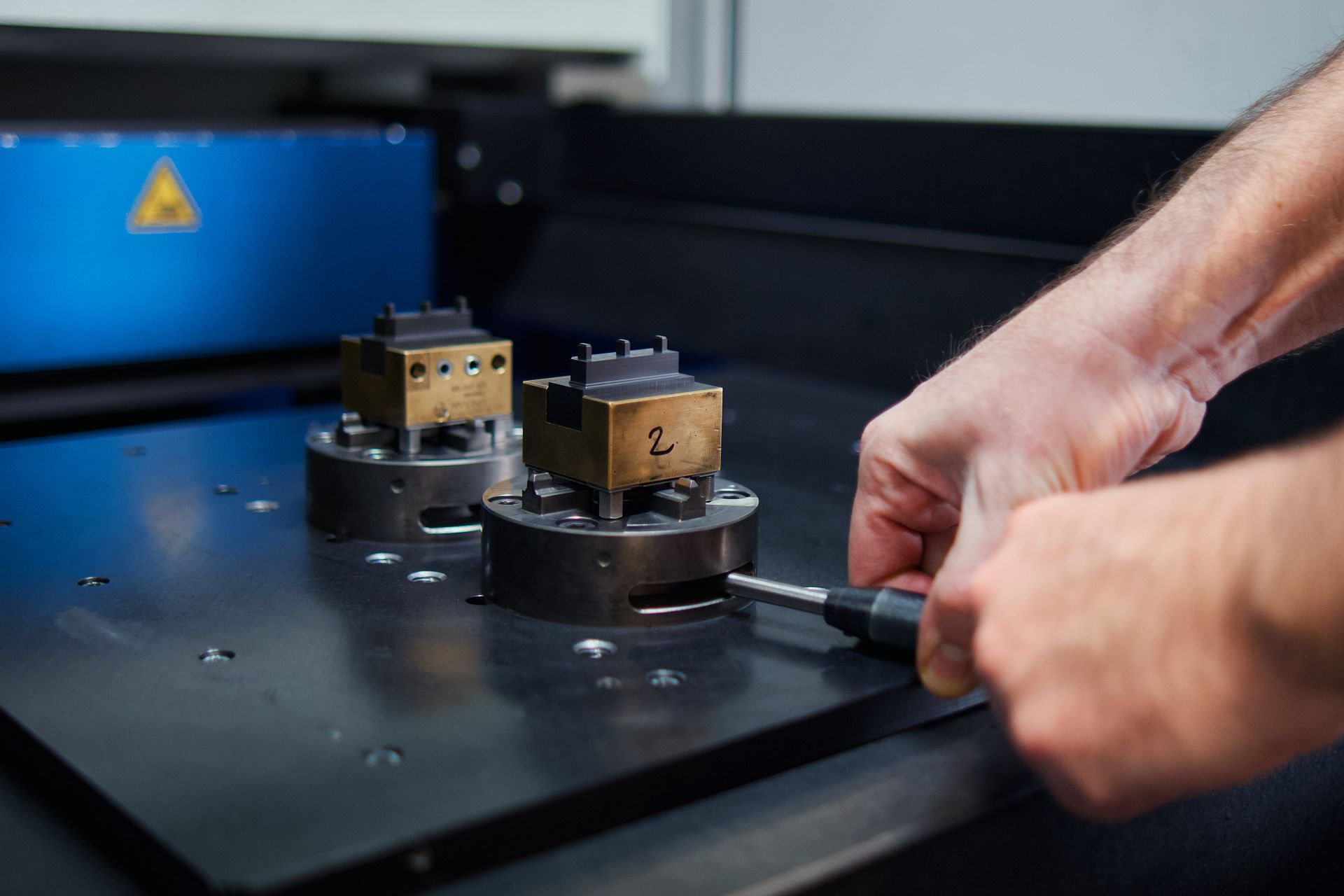

A crucial part of our production process is our fully equipped mould-making facility. Here, we can build, modify and optimise moulds without having to rely on external suppliers. This makes us unique: whereas many companies have to wait weeks for tooling modifications, we can make changes almost immediately.

The mould-making workshop is equipped with:

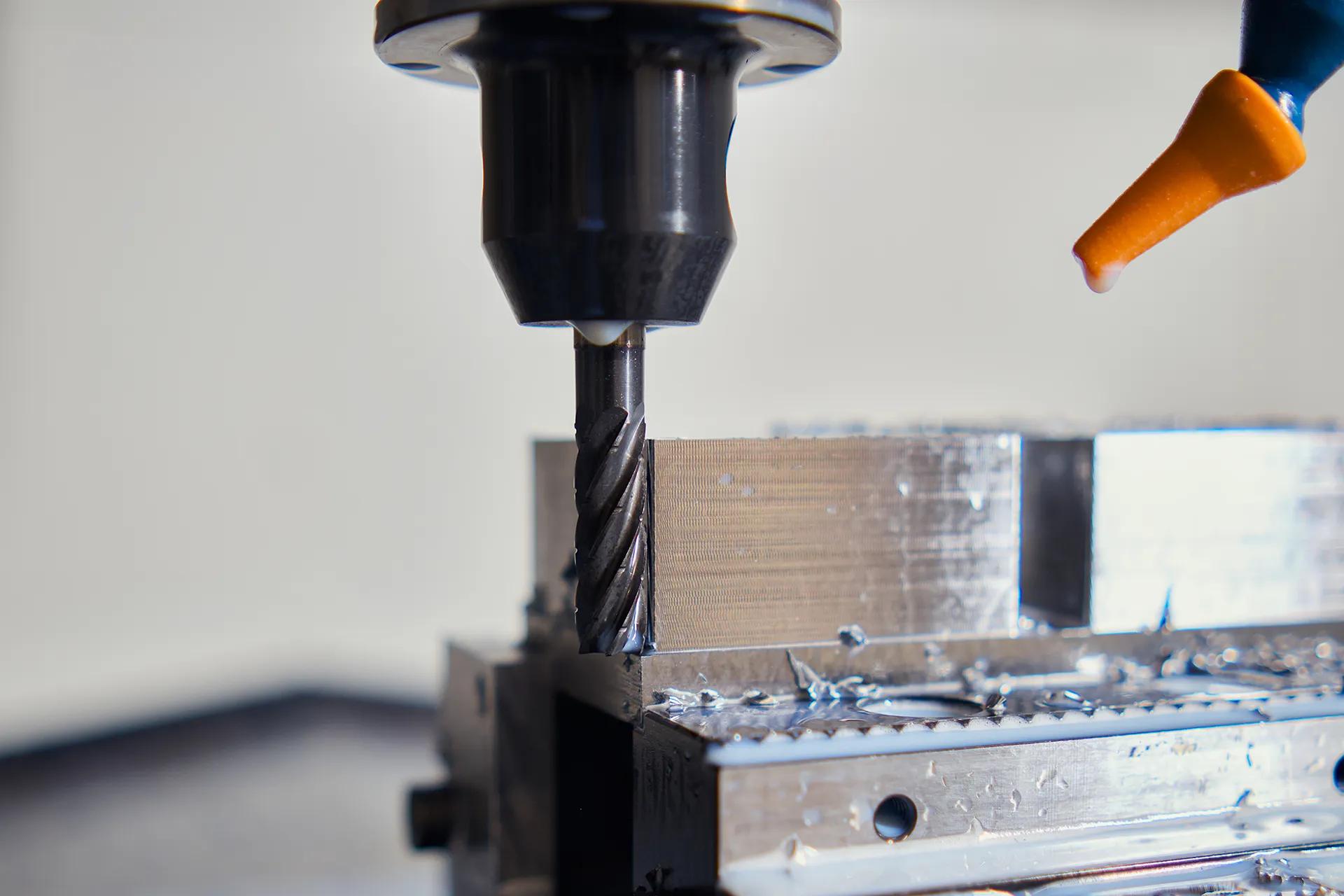

- CNC machine tools for producing and modifying mould components

- Precision instruments for testing and fine-tuning moulds

- Tools for quick repairs and optimisations

- Expertise in cooling systems, discharge chutes, parting lines and rib structures

- 3D printers for rapid production models

This combination of technology and knowledge makes it possible to intervene immediately when optimisations are needed during the production process. This ensures high quality and short lead times.

On-the-job prototyping and iteration without delay

The strength of the PEZY Factory lies in its ability to continue learning and improving during the production process. By creating prototypes on the job and producing small series immediately, a rapid cycle of testing and optimisation is created. This is exactly what small batch production is for: working flexibly, learning from every step and getting closer and closer to the perfect product.

Large injection moulding companies are often geared towards mass production and cannot offer this flexibility. Our approach makes it possible to switch quickly, implement adjustments immediately and retest straight away. This allows us to identify problems at an early stage and demonstrate whether a product is ready for upscaling as early as the pilot phase.

Rapid Market Validation as the basis for success

Our approach fits perfectly with the principle of Rapid Market Validation: quickly validating a product concept using realistic test series. By producing small batches that are representative of the end product, technical and commercial assumptions are tested early on in the process.