With entrepreneurship, expertise, and vision, product development agency PEZY has spent the past thirty years growing into an innovation partner for brands such as Philips and Nivea. Founder Henco Pezij, a driven entrepreneur who spots and seizes opportunities, likes to look beyond the beaten path.

A recent example is the acquisition of O4 Wheelchairs, a manufacturer of high-quality wheelchairs. “Indeed, there’s hardly any plastic involved in that,” says Henco Pezij, in our conversation together with Business Unit Manager Jan-Paul van der Voet at the brand-new Groningen location. “We see the healthcare sector as an important growth market. O4 has a distinctive product, entirely conceived, designed, developed, produced, and brought to market in-house. With this step, we’ve gained a company with proven expertise in metalworking and an established position in healthcare.”

Pezij grew up in Roden, studied mechanical engineering in Enschede, and began as an engineer in Groningen thirty years ago. “We started with just a desk and a few computers. But we quickly realized: if you really want to make a product great, you have to be able to make it yourself. So we bought an injection moulding machine and started developing moulds. That’s how we closed the learning loop. By now, we cover the entire process, from idea to industrially manufacturable product.”

The Pilot Factory plays a central role in that process. It houses two injection moulding machines (Demag, 50 and 100 tons), a full-fledged mould-making workshop, a Plastics Lab, and a comprehensive materials inventory. The lab conducts tests on tensile strength, impact, shrinkage, texture, and mould flow. There’s also an industrial 3D printer for rapid iterations and a blow moulding machine for prototypes.

“In-depth knowledge of the ‘back end’ of product development means PEZY knows exactly what’s technically and economically feasible, even in larger volumes,” says Pezij. “That helps us design robustly, so a product not only works but also maintains consistently high quality on the market.” Van der Voet adds: “When designers work directly with a manufacturer, they get what the manufacturer can produce, not necessarily what’s best for the product. We design independently of production interests, always looking for the optimal solution first. Only then do we find the right production partner.”

Eindhoven, Houten and Singapore

Currently, 35 employees work in Groningen. PEZY also has offices in Eindhoven (2006) and Houten (2008), and since 2012, an international hub in Singapore. Pezij explains: “During my MBA in 2008, I suddenly saw the Netherlands from a distance, as a small but well-connected player in a global market. Many of our clients already had international supply chains and worked with Asian partners. We wanted to help them properly organize production in countries like Malaysia and Indonesia, so we chose to establish a presence in Singapore.”

“If you really want to make a product great, you have to be able to make it yourself”

Singapore serves as a strategic hub for supplier collaboration and as a bridge to regional partners. “We source many moulds from there and have several long-term collaborations with manufacturers of technical plastics.”

Function Development

Van der Voet: “Our clients often have a lot of in-house knowledge themselves, but we add something that they and many producers in Southeast Asia can’t easily offer: high-quality functional development. The Dutch development process is structured, iterative, and highly focused on integrating design and engineering, an approach not yet widespread globally.”

“Large organizations sometimes struggle with their own scale and complexity, making it hard to develop quickly and deeply at a functional level. We’re designed to operate nimbly and effectively in that space. And while other regions are catching up fast, we still have an advantage here, one we’re eager to use for our clients.”

AI

To maintain its lead in product development, PEZY is experimenting broadly with artificial intelligence (AI). Pezij: “For now, it’s still fairly informal. Everyone in the team explores what’s relevant to their own work. But I’m convinced that access to and smart use of AI will soon determine companies’ competitive edge.” He sees major potential especially in design processes: “Humans should always stay in control. But in CAD work, for example, there’s enormous efficiency to be gained.”

“I’m convinced that access to and smart use of AI will soon determine companies’ competitive edge”

Every small change in a design takes dozens of actions. Automating part of that speeds up work and ensures consistency. “AI can help us develop that kind of intelligent design software,” Pezij says.

Henco Pezij emphasizes that it is essential for an organization to keep innovating continuously: “You automatically move along with existing customers, because their needs change. But if you also want to attract new customers, you have to look ahead and anticipate questions that are yet to come. Technologies like AI help us do that.”

Circular thinking

Although the plastics industry in the Netherlands has seen production shift abroad for decades, Pezij still sees opportunities, by focusing on smart, future-proof solutions.

“The core insight is that plastics themselves are no longer a growth market in the Netherlands. But what is growing is the need for smarter, more sustainable applications. That’s where we can make a difference, by thinking ahead about what’s really needed and what can be improved.”

“When Michael Braungart introduced Cradle-to-Cradle (C2C) in 2010, we took that development seriously right away. We took training, got accredited, and have since actively applied circular design principles.” That early investment is now paying off: “The transition is slow but unmistakable. In the past five years, demand has grown: from clients, consumers, and importantly, marketers. Sustainability is no longer an abstract ideal; it’s now a concrete part of product development.”

Design for Recycling and Recyclate

Demand for product development using recycled materials is rising globally, especially among major brands wanting to make existing products more sustainable. “Design for recycling is something more and more organizations are pursuing,” says Pezij. “We’ve built strong expertise in this area: from material properties and processing to chain collaboration and regulation.”

PEZY participates in several EU consortia, including PolyCE. From that project, employees Thijs Feenstra and Joop Onnekink initiated the book Design for & from Recycling, a practical guide for circular product design. They’re now working on a follow-up: INCREACE, a practical recycling assessment tool, again in book form, due out this summer. “The goal is to help companies assess and improve the recyclability of their products.”

Safety and Toxic Substances

Toxic substances are an increasing concern in the recycling industry. Especially when reusing materials, understanding chemical composition and safety is crucial.

“We want to master the entire loop, from material selection to safe reuse,” says Pezij. “That’s why we work closely with suppliers and material specialists to understand exactly what’s in recyclate and how to avoid potential risks.”

“Plastics are not a growth market in the Netherlands. What is growing, however, is the demand for smarter, more sustainable applications”

This is especially vital in sectors with strict safety standards, such as health tech and care, where PEZY collaborates on products requiring material reliability and safety.

At the same time, Pezij also sees opportunities elsewhere: “In consumer products, growth may be flatter, but in fast-moving consumer goods like dispensers and complex packaging systems, demand is still rising. That’s exactly where recyclate can be applied well, as long as we can fully guarantee safety.”

Examples of our developed products

Pezy develops innovative products for diverse markets, ranging from consumer goods to medical devices.

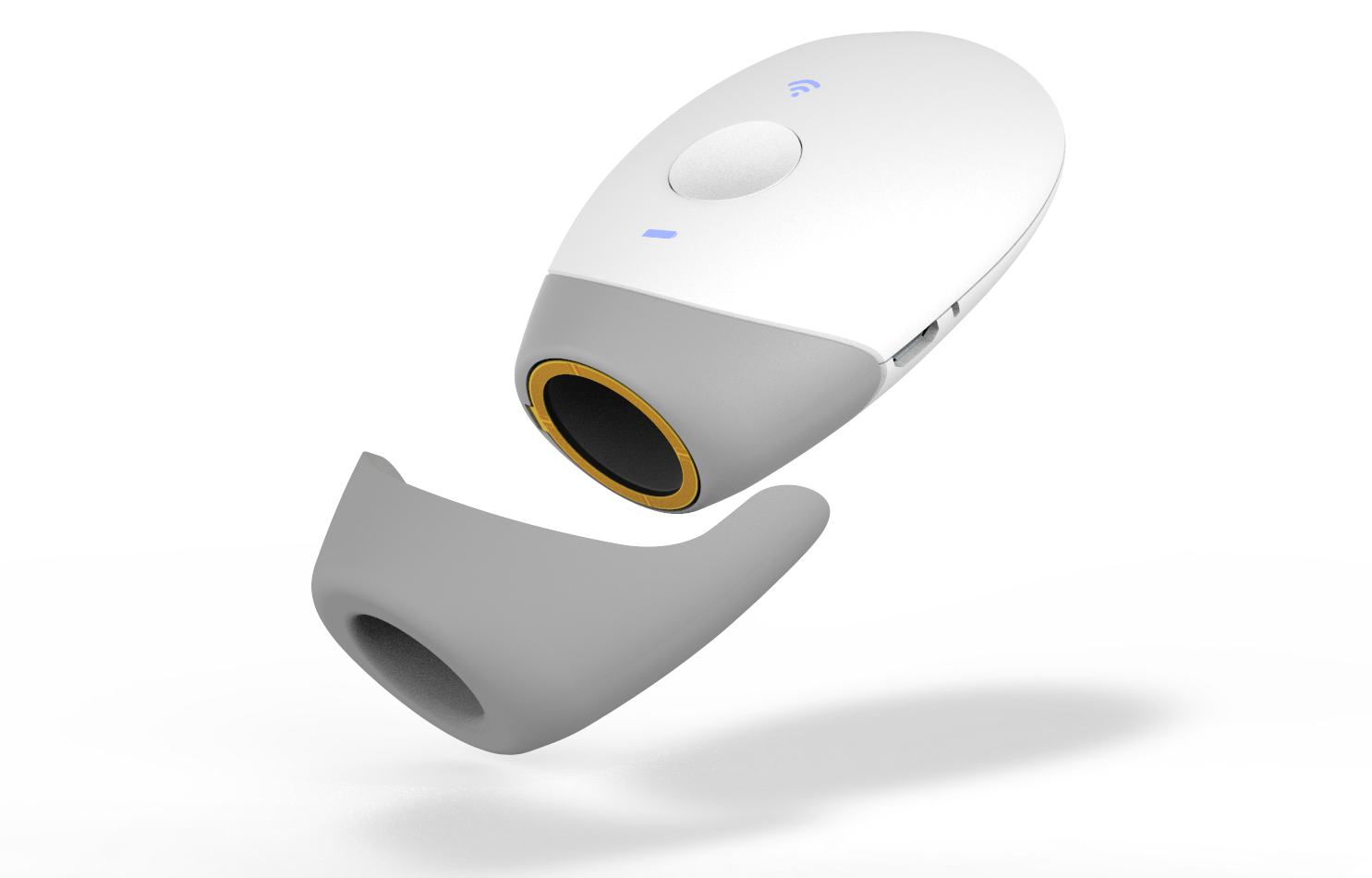

Skinly

Understanding your skin through Artificial Intelligence

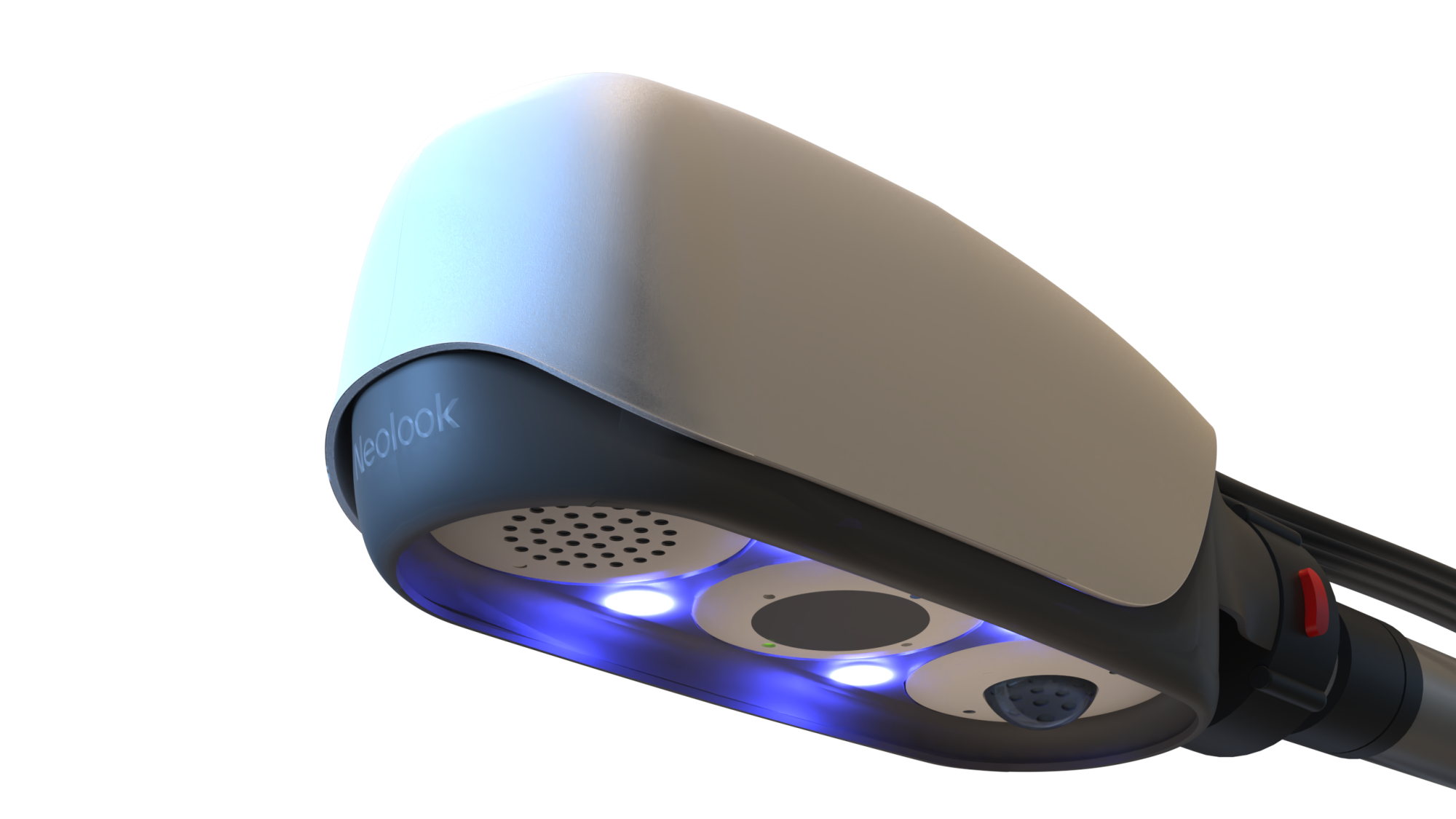

Neolook One

Video-Augmented Monitoring in Neonatal and Pediatric Care

Hable one

An ingenious braille-operated keyboard for improving multimedia accessibility for the visually impaired

Victron Energy EV Charger

An EV car charger specifically designed for the home market

Philips Living Color

Unique product with PET bottle technology

Quva

Less waste, fresh for longer

Philips Avent

Smart details and materials for comfortable breast pump

Dorel Quinny

The First-Ever Foldable Plastic Buggy

Scale-ups

Scale-ups are an important client group for PEZY. The agency invests actively in collaborations with young, fast-growing companies, guiding them in co-creation from idea to production-ready design. “We love working with entrepreneurs who truly want to bring something new,” says Pezij. “Often, we help from the first sketch or concept and build together toward a scalable, manufacturable product.”

The earlier a scale-up gets in touch, the better: “Sometimes a client comes in with a 3D-printed prototype with a design that’s not suited for injection moulding. In that case the design has to be largely redeveloped, which is a waste of time and investment, so early alignment is crucial.”

The Future

Over the decades, PEZY has evolved into a company mastering the full chain, from idea to finished product. That took time and careful building, followed by expansion into Asia. Although the world has changed since, with COVID-19, geopolitical shifts, and evolving customer behaviour, the agency keeps thinking ahead.

“You can’t foresee everything, but you must be ready to act,” says Pezij. He’s now focused on the next major step: growing from 70 to 120 employees. “Such a scale jump requires a fundamentally different way of organizing. You want to retain agility while professionalizing structure.”

PEZY aims to stay lean, since many clients value its speed and flexibility. “We can often deliver a mould within days. That agility is key to our proposition,” Pezij notes. Yet growth brings economies of scale: “Overhead costs like IT only become efficient when you grow, so you need to make smart choices.”

The international dynamic remains a factor: clients increasingly work with production partners in low-wage countries. To stay relevant, PEZY focuses on technical depth and innovation. But full relocation abroad isn’t desirable. “We believe in local ownership. Every branch should independently add value, for clients and for its people. We always lead from source, from the Netherlands. That’s how the organization stays strong and agile.”

Smart Decoupling in the Value Chain

When outsourcing parts of the development process, choosing the right moments is crucial. According to Pezij, there are three logical “decoupling points”:

- After concept development, when the direction is clear.

- After prototyping, when the design is finalized and intellectual property is secured.

- After detailed design, when you can support production partners with moulds and tooling.

“If you manage that carefully, you remain valuable as a development partner,” says Pezij. “That’s why we invest continuously in knowledge, about materials, processes, and circularity. Our specialists work daily with clients and suppliers to validate new materials such as recyclate and biobased plastics. Because applying them is never a standard process. Every innovation is custom work. That’s how we turn ideas from nothing into something valuable, and stay relevant in a changing world.”

“Plastics are not a growth market in the Netherlands. What is growing, however, is the demand for smarter, more sustainable applications”